SealMaster Introduces CrackPro Robotic Maintenance Vehicle

Safety, Efficiency Spark Development of Award-Winning RMV

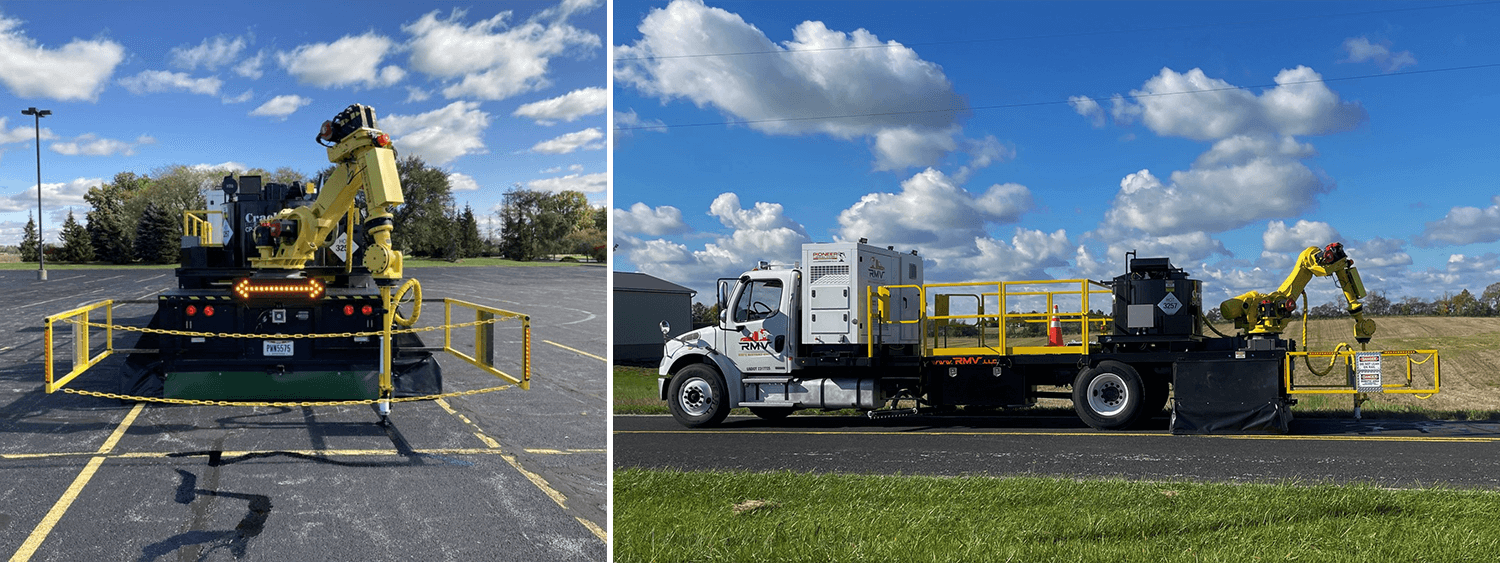

Safety and efficiency inspired development of the CrackPro Robotic Maintenance Vehicle (RMV). Minimizing labor and keeping crew members off the road, It requires just a driver and a person who stays on the back of the unit to monitor application and replenish the crack sealant. The CrackPro RMV’s advanced AI vision system measures and scans cracks, controls material flow, communicates with a robotic arm, and guides the wand and shoe of the heated hose to dispense crack sealant, after the automated blower system cleans cracks for sealing.

The RMV features a full truck chassis, equipped with a FANUC R2000 robot, generator, integrated blow-off system, custom Crack Pro 260, LED safety lights, and rear safety cage to alert drivers. In addition to reducing labor and enhancing safety, the CrackPro RMV, conserves material and money. “It makes precise decisions, runs at a consistent speed, and can cover three shifts a day with fewer people,” says RMV representative Tyler Roth.

Todd Hendricks of Pioneer Industrial Systems came up with the concept when he saw a crack sealing crew on his way to work in late 2019. Then, he proposed a challenge: “How could we apply our robotics expertise to increase safety and efficiency in routine road maintenance?” The company soon established its RMV division, and ultimately partnered with SealMaster on the venture.

The CrackPro RMV began its tour of industry trade shows in February. It will next be featured at the American Public Works Association’s PWX conference Aug. 2 – 5. SealMaster and RMV continue to host numerous demonstrations coast to coast for contractors and local, state, and federal public works agencies. It will also be featured at the Department of Defense Showcase Oct. 26 – 29.

The CrackPro RMV earned Pioneer Industrial Systems the Fanuc America 2022 Innovative System of the Year award, and the 2021 AFWERX Flightline of the Future Challenge for Airfield Maintenance and Repair. Fanuc is a leading global supplier of robots. AFWERX is an innovation arm of the Department of the Air Force, supporting both the U.S. Air Force and U.S. Space Force.

To request a demonstration, call 800-395-7325, email chale@sealmaster.net, or click “contact us” at SealMaster.net and submit the online form with you contact information.

About SealMaster

SealMaster, the nation’s One-Stop Source for pavement maintenance products and equipment, is the world’s leading manufacturer of pavement sealer with more than 100 locations in the United States, including Puerto Rico; licensed manufacturing in China and Mexico; and distribution in more than 50 countries. In addition to pavement sealer, the company distributes pavement crack sealants and repair materials, traffic paints, dust suppressants, tools, accessories, sport surfacing products, and equipment to apply all the materials. The company maintains its industry leadership consistently introducing high-performance, innovative pavement sealer formulations and state-of-the-art manufacturing technologies. Pavement maintenance professionals, property managers and owners, municipalities and others charged with pavement maintenance use SealMaster products and equipment to protect, preserve and beautify asphalt and concrete pavement. For more information, visit sealmaster.net.

About RMV

Robotic Maintenance Vehicles began with a concept from Pioneer Industrial Systems to provide safer work zones for our nation’s highway maintenance crews. The concern was recognized by the president of PIS, when he noticed how dangerous crack sealing and other basic road maintenance tasks are. To bring this concept to life, RMV has integrated an R2000 onto a truck chassis, equipped with components that create a more efficient form of work. RMV performs faster and more accurate maintenance, reducing the amount of equipment and labor needed, conserving material and money, and keeping roadworkers out of harm’s way.