Asphalt Sealcoating

Protect & Beautify Asphalt Pavement

Asphalt Sealcoating is the Smart Choice for Pavement Preservation.

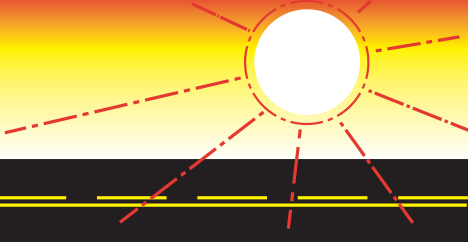

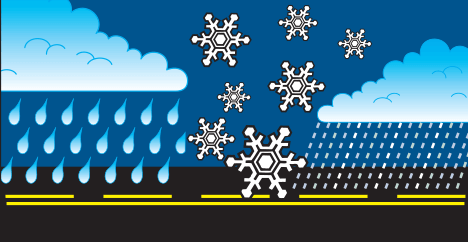

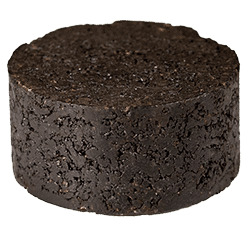

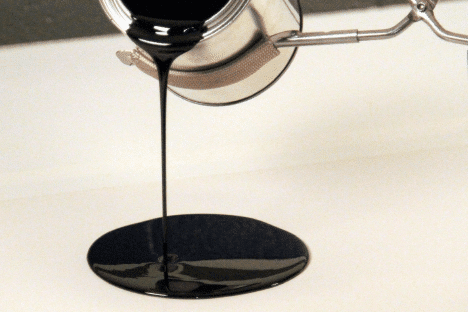

Asphalt pavement is mostly rock and/or stone and gravel, along with a binder. The rock, or aggregate, is held together with this binder known as asphalt cement. Maintaining this binder is essential to preserve the service life of asphalt surfaces. Rain, U.V. rays, and chemicals, as they are introduced into the asphalt, will degrade the binder and thus begin the degradation process of the asphalt. This will continue and create a surface that turns brittle. So, the purpose of asphalt sealcoating is to protect the asphalt pavement and to beautify at the same time. The earlier an asphalt sealer can be applied in the life cycle of asphalt the better.

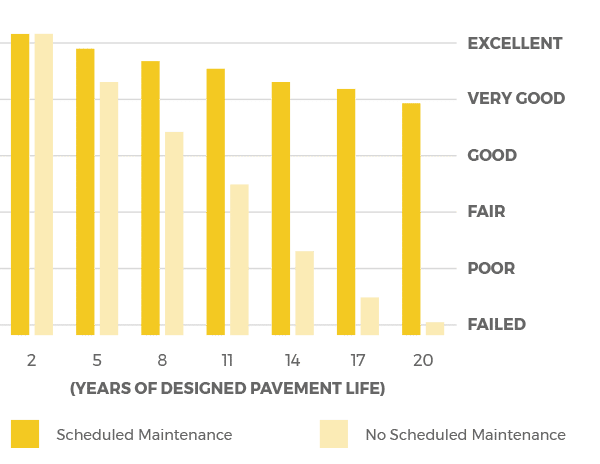

Sealcoating Increases Pavement Service Life

To reduce the effects of the above-mentioned elements, it is important to implement a maintenance program that utilizes sealcoating to extend the life of your parking lot or driveway. Sealcoating will provide a layer of protection blocking out harmful intrusions such as water, oils, and U.V. damage. In addition, when asphalt sealer is applied to manufacturers’ specifications, sealcoating provides a slip-resistant surface with a deep black finish that beautifies the parking lot or driveway. Asphalt sealers are typically bituminous based products or acrylics. The sealcoat is in a liquid formulation of one of the above emulsions, mixed with water, silica sand, polymer additives, and other proprietary fillers and solids. These products can be applied by brush, spray or squeegee.

A regularly scheduled sealcoating program will more than double the life of the asphalt, saving you significant dollars down the line.

Instead of having to pay thousands of dollars for new pavement, it is more cost effective to spend only pennies on the dollar per square foot to maintain.

What is Asphalt Pavement?

Asphalt Pavement, also known as Hot Mix, is a simple blend of two main components; Molten Liquid Asphalt (the black glue or binder), and Crushed Rock or Aggregate.

The Hot Mix is then placed and compacted to form asphalt pavement.

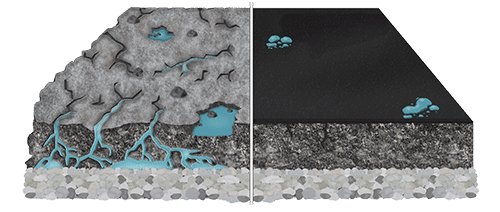

Unsealed vs. Sealed

Your Parking Lot is the “Welcome Mat” to Your Property.

It provides both image and functionality to business or institution. Your parking lot represents a substantial capital investment that must be maintained.

A scheduled program of pavement maintenance that includes sealcoating and crack filling will more than double the life of your asphalt pavement and provide maximum curb appeal.

Sealcoating and crack filling are a fraction of the cost of repairing or replacing asphalt pavement.

Free Pavement Inspections & Estimates

Local Sealcoating Contractors in your Area

Tips for Applying Asphalt Sealcoating

When applying a sealcoating product, follow the important steps referenced below to get the most protection and optimum performance:

- A minimum of two coats should be applied.

- Temperatures must be a minimum of 50 degrees and rising for a period of not less than 24 hours. Do not apply when temperatures are forecasted to get below the 50-degree mark.

- Do not apply if rain is imminent within the same 24 hour period.

- Once finished with the application of sealcoat, allow to cure 24 hours before allowing vehicle traffic back on the surface.

Before Sealcoating

After Sealcoating

Sealcoating Protects & Beautifies Asphalt Pavement

Sealcoating with SealMaster® pavement sealer replenishes the binder that is lost through weathering and aging and provides a barrier to moisture intrusion as well as ultraviolet rays, chemicals, and salt.

And just as important, sealcoating beautifies pavement; enhancing the image and curb appeal of commercial properties, home driveways, roadways and more. Sealcoating provides a rich, black “like new” appearance to otherwise drab and worn out pavements.

Why Does Asphalt Pavement Deteriorate?

Left untreated, asphalt pavement will deteriorate rapidly. The asphalt binder (glue) that holds the pavement together begins to oxidize and weather soon after installation. Moisture penetrates the asphalt, causing damage and deterioration to the pavement. Oil, gas, and salt cause further damage to the pavement surface. All of this environmental distress is why asphalt goes from a newly laid fresh black appearance to a drab, aged, oxidized gray appearance.

SealMaster manufactures a full line of sealcoating technologies for asphalt and blacktop. Professional pavement maintenance contractors look to SealMaster more than any other brand of sealcoating when it’s time to sealcoat.

Whether you are in need of driveway sealer or sealcoating materials for parking lots, SealMaster will exceed your requirements. From roads and streets to all other types of asphalt and blacktop paving, SealMaster is the #1 Name in Pavement Sealer and Asphalt Sealer.