Asphalt Crack Filling & Sealing | Crack Filler

Provide a Water-Proof Barrier

Crack Sealing is an Integral Component of an Effective Pavement Preservation Program.

A scheduled program of pavement maintenance that includes sealcoating and crack filling will more than double the life cycle of your asphalt pavement and provide maximum curb appeal. Sealcoating and crack filling is a fraction of the cost of repairing or replacing asphalt pavement. The key to effective crack filling and sealing is to repair and fill the cracks while they are small, as crack filling inhibits crack growth and keeps new cracks from forming.

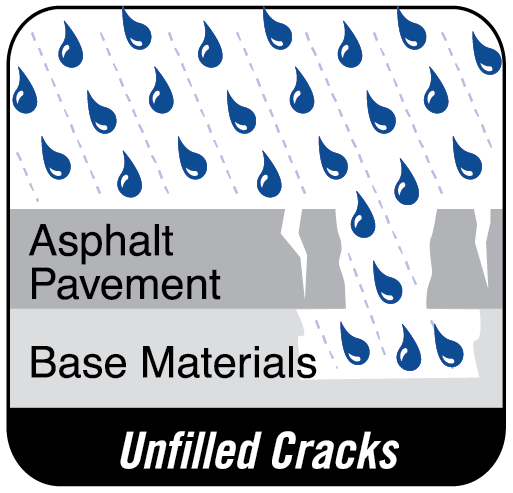

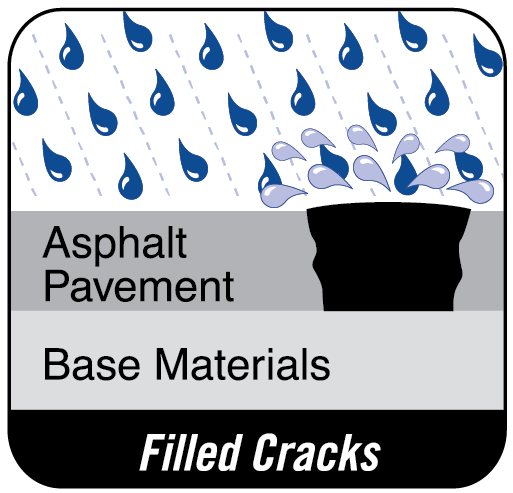

Crack Sealing Provides Superior Protection Against Moisture Intrusion – The Leading Cause of Pavement Failure.

Left unfilled, cracks will allow rain and moisture to flow through pavement and erode base materials ultimately resulting in potholes and pavement failure. Filling cracks with crack filler helps prevent rain and moisture from flowing through the pavement and causing erosion or failure. By stopping the entrance of water, the rate of deterioration of the pavement is significantly slowed. Crack sealing also prevents the loss of aggregate from the edges of the crack.

What is Cold Applied Crack Filling & Sealing?

Cold Applied Crack Filling and Sealing provides an efficient, economical and effective approach to filling and sealing cracks in asphalt pavement. “Filling” and “Sealing” are terms that are used interchangeably in the pavement maintenance industry. Both terms essentially mean the same thing with some attributing the term “Sealing” to strictly rubberized elastomeric materials. Cold applied crack filling is typically performed on parking lots and driveways, but can also provide effective results on roads and streets. Cold Applied Crack Fillers typically consist of a clay-filled, polymer-modified asphalt emulsion liquid that flows into cracks at ambient temperatures.

What is Hot Pour Crack Filling & Sealing?

Hot pour cracking involves heated up blocks of rubberized asphalt in a specially designed oil-jacketed melter and then applying the heated material to cracks in roads and parking lots. Hot pour crack filling and sealing is generally done on roads and highways and in many cases, on parking lots. Hot pour offers the advantage of quick set times (10 minutes or less). Once the hot pour material cools you can drive on it.

Free Pavement Inspections & Estimates

Local Sealcoating Contractors in your Area

Cold Pour Convenience – Hot Pour Performance

TruFlex is a highly rubberized crack sealant designed for sealing cracks in asphalt or concrete pavements. TruFlex can also be mixed with sand for filling larger cracks and alligatored areas.

Revolutionary Crack Filling Technology

TruFlex Rubberized Crack Sealant

- Ideal for use as a high-performance crack sealant for asphalt and concrete pavements

- Also designed for mixing with sand to repair larger cracks and alligatored pavement

- High softening point and toughness helps resist ripping and tearing in high temperatures

- Superior UV and fuel resistance

Hot-pour and cold-applied technologies are available through SealMaster. Many specifications can be met or exceeded with many of SealMaster’s hot-pour solutions. CrackMaster materials are the featured products meeting the demands that hot applied products can achieve. Products such as FlexMaster and TruFlex offer the convenience of cold-applied methods with the performance normally associated with hot-melt.

Your local SealMaster can also supply you with the recommended equipment for application of crack sealants and fillers. If you have a property-based performance crew or looking to try out new equipment, SealMaster locations also offer rental programs as well.