Choosing the right sealcoating equipment is one of the most important decisions a contractor can make. The equipment you use affects productivity, job quality, labor efficiency and your ability to scale. With more options on the market than ever, the best approach is to match equipment to your current workload, then plan for what you want your business to handle next season.

With a wide range of equipment configurations available, contractors must evaluate their current operations carefully while planning for future workload demands. This guide outlines the primary considerations involved in selecting sealcoating equipment and explains how different system types support varying operational needs.

What You’ll Learn

- Assessing Job Requirements and Application Scope

- Defining Operational Needs Before Equipment Selection

- Equipment Platforms and System Configurations

- Primary Categories of Sealcoating Equipment

- Tank Capacity and Production Efficiency

- Pump Systems, Agitation and Material Handling

- Transportation, Jobsite Access and Equipment Mobility

- Cost Considerations and Long-Term Equipment Value

- Ease of Use, Maintenance and Safety

- Planning for Future Growth

- Learn More About Pavement Protection and Maintenance

- SealMaster Expertise and Support

Assessing Job Requirements and Application Scope

Selecting sealcoating equipment begins with a clear understanding of the scope, scale and type of work being performed.

Contractors should evaluate the following factors:

- The primary types of surfaces serviced, including residential driveways, commercial parking lots, roadways or municipal projects

- Average job size and weekly production volume

- Crew size and labor availability

- Anticipated changes in workload or market focus

Smaller, intermittent projects place different demands on sealcoating equipment than high-volume commercial or municipal work. Aligning equipment capacity and configuration with job requirements helps reduce inefficiencies, limit downtime and avoid premature equipment replacement.

Defining Operational Needs Before Equipment Selection

Before comparing specific equipment types, contractors should define how sealcoating equipment will be used on a daily basis.

Key considerations include:

- Required production rate to complete jobs efficiently

- Preferred application method based on surface type and customer specifications

- Material handling requirements, including additives and aggregate

- Transportation, storage and jobsite access limitations

Establishing these operational requirements allows contractors to evaluate equipment configurations that support consistent application and efficient daily production.

Equipment Platforms and System Configurations

Sealcoating equipment is available in several platform configurations. Each configuration affects mobility, capacity, storage requirements and how equipment integrates into daily operations. Understanding these platforms provides a necessary foundation for evaluating specific sealcoating equipment and application methods.

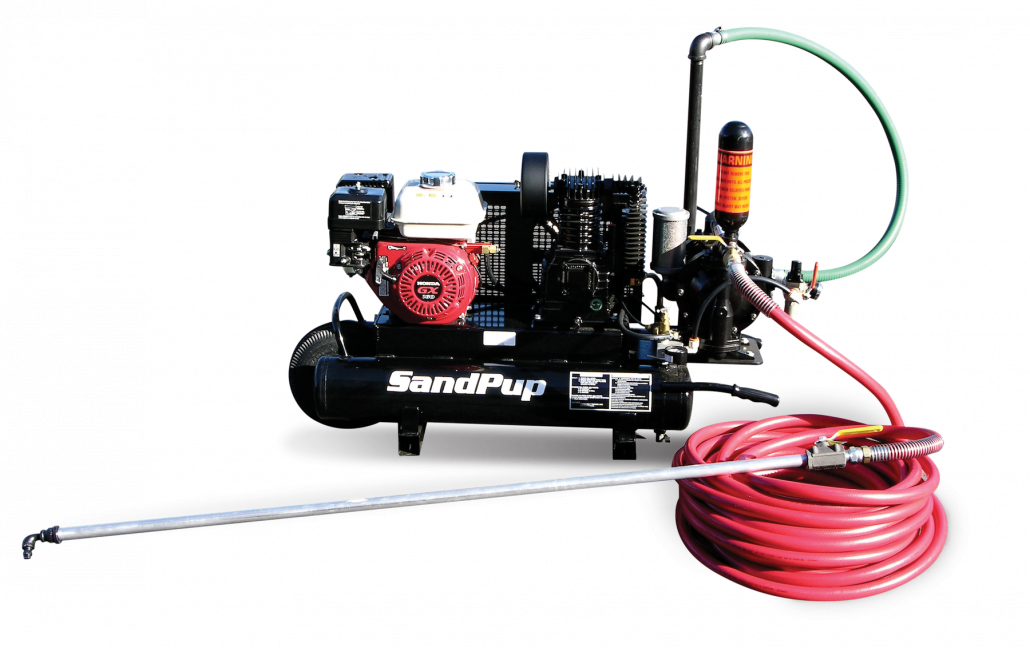

Portable Systems

Portable sealcoating equipment is designed for maximum mobility and ease of transport. These systems typically feature lower material capacity and aremoved manually and loaded onto a vehicle as needed.

Portable systems are commonly used for:

- Residential driveways and small commercial projects

- Contractors entering the market or adding a supplemental unit

- Operations requiring frequent relocation between job sites

While portable systems offer flexibility, their limited capacity can result in more frequent refilling on larger jobs.

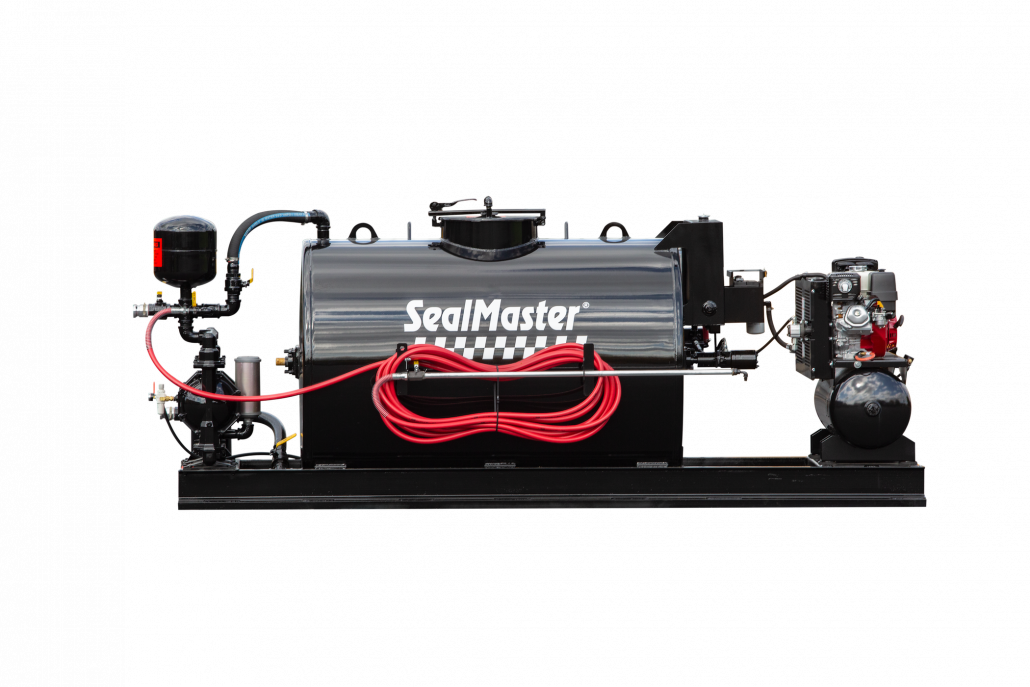

Skid-Mounted Systems

Skid-mounted systems are designed to be loaded into a truck bed and removed when not in use. This configuration allows contractors to utilize shared vehicles or store equipment separately between jobs.

Skid-mounted systems are often selected by contractors who:

- Require flexibility in vehicle usage

- Operate multiple crews with shared equipment

- Need moderate to high production capacity without a dedicated trailer

This platform offers a balance between portability and increased material capacity.

Trailer-Mounted Systems

Trailer-mounted systems provide higher material capacity and dedicated transport. These systems are designed for contractors who require increased daily production and reduced downtime caused by refilling.

Trailer-mounted systems are commonly used for:

- Commercial parking lots and large residential routes

- High-volume production schedules

- Operations where sealcoating is performed regularly

This configuration allows equipment to remain set up and ready for use, improving efficiency across multiple jobs.

Truck-Mounted Systems

Truck-mounted systems are permanently installed on a vehicle and offer the highest material capacity and production capability. These systems are typically used by contractors who perform sealcoating as a primary service.

Truck-mounted systems are well suited for:

- Large commercial or municipal projects

- Contractors requiring maximum daily output

- Dedicated sealcoating operations with consistent workload

Permanent installation supports higher production rates, integrated material handling and reduced setup time, though it limits flexibility in vehicle use.

SealMaster offers custom truck-mounted sealcoating systems designed around specific vehicle platforms, production requirements and jobsite demands. These systems can be configured to support tank capacity, pump selection, spray bar options and material handling features that align with high-volume sealcoating operations.

Learn more about SealMaster custom truck mounting options and available configurations.

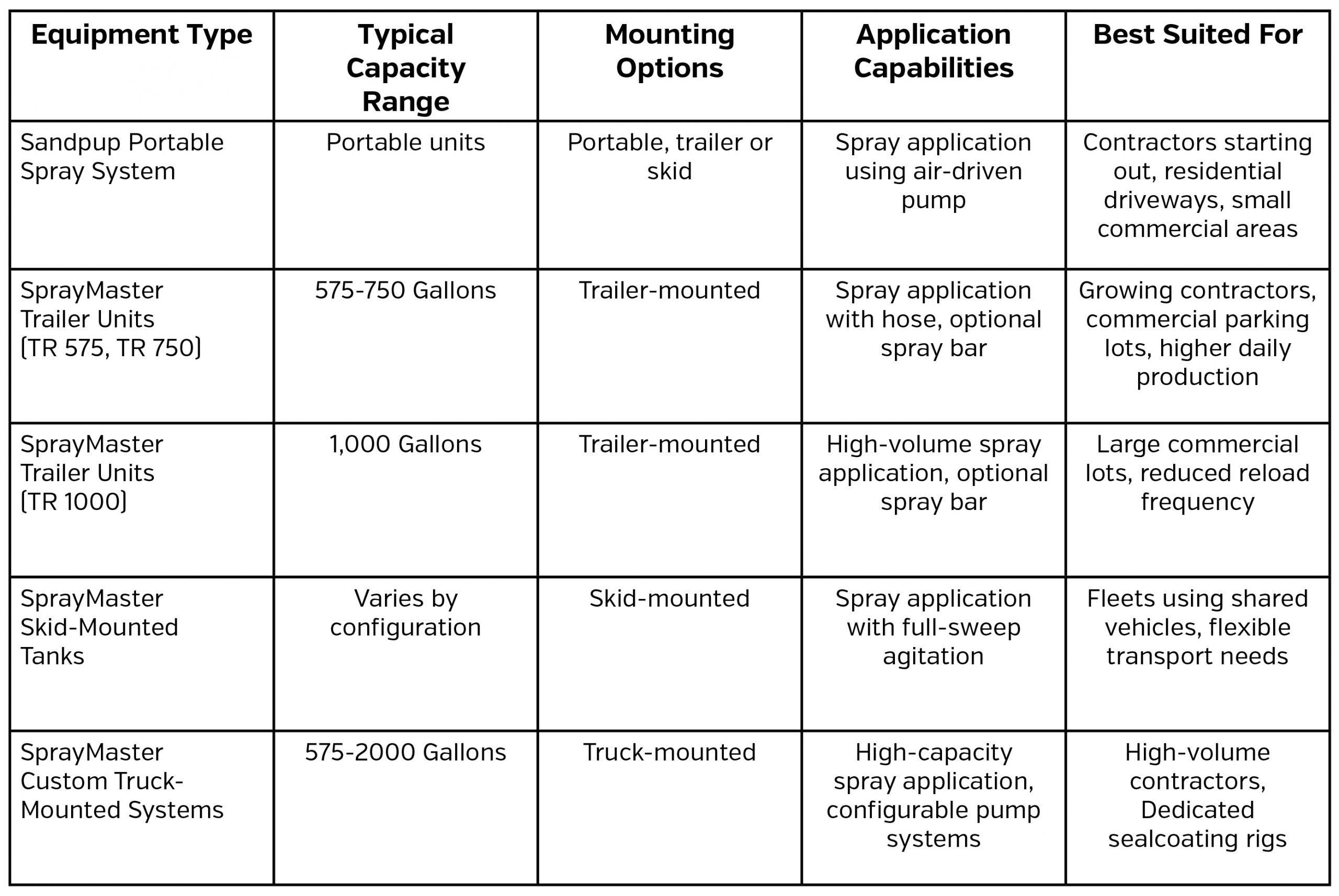

Primary Categories of Sealcoating Equipment

Sealcoating equipment generally falls into three primary categories. Each category is designed to address different production demands, application preferences and pavement conditions. Understanding these distinctions is essential when selecting equipment that aligns with both current operations and future growth. These categories reflect differences in application method, production capability and surface conditions rather than equipment quality.

Spray Application Equipment

Spray application systems are designed to deliver uniform coverage at higher production rates. These systems are commonly used on larger surfaces and routes that require consistent output throughout the workday.

Spray application equipment is commonly selected when:

- Large surface areas require efficient material distribution

- Production speed and consistency are priorities

- A uniform finish and appearance are desired

From an application standpoint, spray methods distribute sealer evenly across the pavement surface, coating the tops of the aggregate while allowing material to enter surface pores. On well-prepared pavement, spray application provides efficient coverage while maintaining professional appearance standards.

SealMaster manufactures spray sealcoating equipment in trailer-mounted, skid-mounted and truck-mounted configurations. These systems are engineered to handle sealcoating materials with or without sand, allowing contractors to work with a variety of mix designs and production demands without changing equipment platforms.

For more details on spray equipment, review the full lineup of SealMaster spray sealcoating equipment.

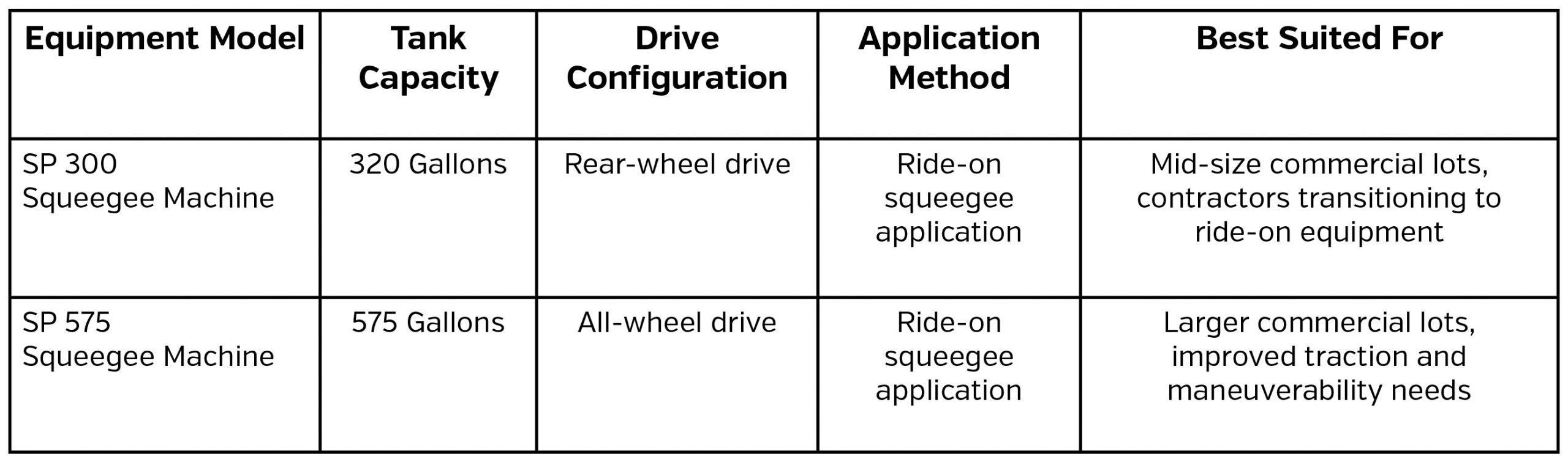

Squeegee Application Equipment

Squeegee application systems are typically configured as self-propelled, ride-on machines designed for controlled material placement and consistent coverage across large pavement surfaces.

Squeegee application is commonly selected when:

- Pavement texture or surface porosity requires deeper sealer penetration

- Application control is a priority

- Crews are working on large, open areas with minimal obstructions

From an application standpoint, the squeegee method physically works sealer into the pavement surface, helping fill small voids and surface irregularities. This approach is often used as an initial coat on older or more porous asphalt where additional penetration and material build are desired.

SealMaster squeegee equipment is designed to support controlled application while maintaining consistent production rates on mid-size and large projects. These machines are engineered to apply sealcoating materials with or without sand, providing flexibility across varying job requirements without sacrificing performance.

For more details on squeegee equipment, review the full lineup of SealMaster self-propelled sealcoating equipment.

Combination Spray and Squeegee Equipment

Combination systems provide both spray and squeegee application methods within a single machine, allowing operators to transition between spray and squeegee application without changing equipment. This versatility supports consistent production across a wide range of pavement conditions and project requirements.

Combination systems are commonly selected when:

- Projects include both residential and commercial pavement surfaces

- Squeegee application is used for initial coats and spray application is used for finish coats

- Application method flexibility is required across varying job types

From an application standpoint, combination machines allow contractors to adjust material placement based on surface condition and performance goals. Squeegee application can be used to work sealer into the pavement surface, while spray application can be used to build material on the aggregate and achieve a uniform finish.

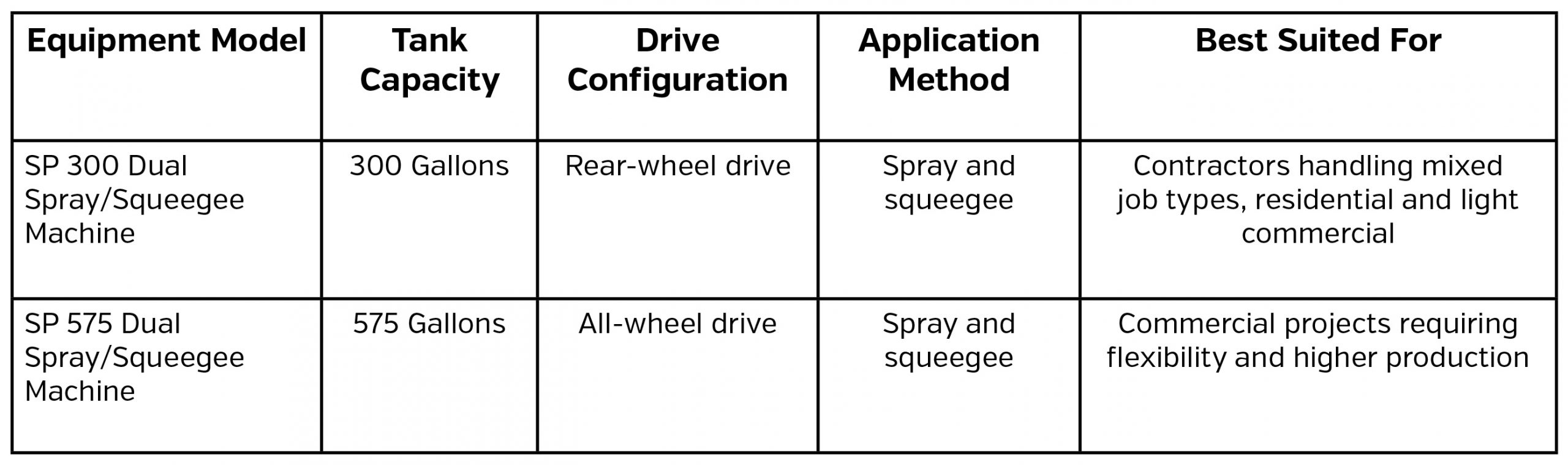

SealMaster offers self-propelled combination machines designed to support both spray and squeegee application while maintaining consistent material handling and production efficiency. These systems are engineered to apply sealcoating materials with or without sand, providing flexibility across different mix designs and project requirements.

For more details, review the full lineup of SealMaster Dual Spray/Squeegee machines.

Tank Capacity and Production Efficiency

Tank capacity plays a significant role in daily production efficiency. Larger tanks reduce downtime associated with refilling, while smaller tanks may offer advantages in maneuverability and initial investment.

When determining appropriate tank size, contractors should evaluate:

- Average square footage completed per job

- Acceptable frequency of material reloads

- Vehicle towing or payload limitations

- Storage considerations during non-operational periods

SealMaster manufactures sealcoating equipment across a wide range of tank capacities, allowing contractors to align capacity with production goals without compromising transport or handling requirements.

Pump Systems, Agitation and Material Handling

Pump performance is central to consistent application and reliable operation. Pump selection should account for material type, production expectations and operational demands.

Key pump and material handling considerations include:

- Required flow rates and pressure levels

- Compatibility with coal tar and asphalt emulsion sealers

- Ability to spray sand

- Full-sweep agitation to maintain uniform material consistency

- Durability under sustained use

- Ease of service and component access

SealMaster equipment is engineered to handle sealcoating materials with or without sand, allowing contractors to maintain consistent mix designs across a range of application requirements without changing equipment platforms.

Equally important is access to service and support. SealMaster operates as a manufacturer-supported service dealer network, providing contractors with in-season parts availability, equipment service and technical support to help keep operations running during peak production periods.

Transportation, Jobsite Access and Equipment Mobility

Transportation considerations directly affect jobsite efficiency and equipment utilization.

Contractors should evaluate:

- Vehicle type and capacity

- Jobsite access and maneuverability

- Storage requirements between jobs or seasons

Skid-mounted systems offer flexibility and portability, while trailer-mounted systems provide higher capacity and integrated transport features. Selecting the appropriate configuration ensures equipment complements daily operations rather than limiting them.

Cost Considerations and Long-Term Equipment Value

Initial purchase cost is only one factor in evaluating sealcoating equipment. Long-term value is determined by durability, productivity and the ability to support growth.

Contractors should consider:

- Expected service life of the equipment

- Maintenance and repair requirements

- Labor efficiency gains

- Capacity to support expanded workloads

Investing in professionally manufactured sealcoating equipment can result in a higher return on investment through increased production capacity, reduced downtime and longer equipment service life. SealMaster equipment is designed to support sustained use in commercial environments, helping contractors complete more work per day while minimizing maintenance-related disruptions over the life of the equipment. SealMaster offers flexible financing programs that allow contractors to invest in appropriate equipment without delaying growth due to capital constraints.

Ease of Use, Maintenance and Safety

Equipment design influences both productivity and jobsite safety. Systems that are straightforward to operate and maintain help reduce training time and operational errors.

Key considerations include:

- Accessibility for cleaning and winterization

- Clear and intuitive control layouts

- Secure hose connections and controlled pressure

- Proper ventilation and material handling practices

- Use of appropriate personal protective equipment

Prioritizing safety and maintainability supports consistent operations and protects both crews and equipment investments.

Planning for Future Growth

Sealcoating equipment should support long-term business objectives, not just immediate needs.

A typical growth progression includes:

- Portable or lower-capacity systems during early expansion

- Skid-mounted or trailer-mounted systems as production increases

- Truck-mounted or ride-on equipment for sustained commercial work

Selecting scalable equipment platforms reduces the need for frequent replacements and allows contractors to grow efficiently.

Learn More About Sealcoating Application Methods

Effective sealcoating depends on both the equipment used and the application method selected. While quality materials provide the foundation for pavement protection, long-term performance and appearance are influenced by how sealer is mixed, handled and applied to the pavement surface.

To better understand how application method and equipment work together, explore our guide comparing spray and squeegee sealcoating methods. This article explains how each technique affects material placement, coverage and finish, and how those differences factor into selecting equipment configurations that support residential and commercial pavement maintenance.

Read next: Spray or Squeegee: Which Pavement Sealer Application Method is Best?

SealMaster Expertise and Support

With more than 60 years of industry experience and more than 3 billion gallons of pavement sealer applied worldwide, SealMaster is recognized as the No. 1 brand of pavement sealer. As a one-stop source for pavement maintenance solutions, SealMaster offers premium products, sealcoating equipment and training through a franchise network of 125+ manufacturing and distribution centers across North America, along with product distribution in more than 60 nations.

This extensive reach ensures contractors, municipalities and property owners get the support they need to maintain and extend the life of their pavement. SealMaster’s national network of professional contractors provides full-service pavement maintenance solutions including pothole repair, crack filling, sealcoating and line striping.

For expert guidance, product recommendations or to connect with a pavement maintenance specialist, contact your local SealMaster for a free inspection or project estimate.