When it comes to protecting and extending the life of asphalt pavement, choosing the right sealer is critical. Contractors and property owners generally find themselves choosing between two major types of sealers: asphalt-based sealers and coal tar sealers. While both are designed to shield pavement from oxidation, chemicals and general wear, they perform very differently. Understanding those differences can help you choose the best sealer for your project, your climate and your long-term maintenance goals.

What You’ll Learn

- Understanding the Divide in the Sealcoating Industry

- Why Coal Tar Sealers Have Historically Dominated the East

- Why Asphalt-Based Sealers Lead in Western Markets

- Chemical Differences: Coal Tar Pitch vs. Petroleum Asphalt

- How Asphalt and Coal Tar Sealers are Made

- Durability & Flexibility

- Fuel & Chemical Resistance

- The Eastward Shift: Growing Popularity of Asphalt-Based Sealers

- Future Outlook: Continued Growth and Innovation

- SealMaster Expertise and Support

Understanding the Divide in the Sealcoating Industry

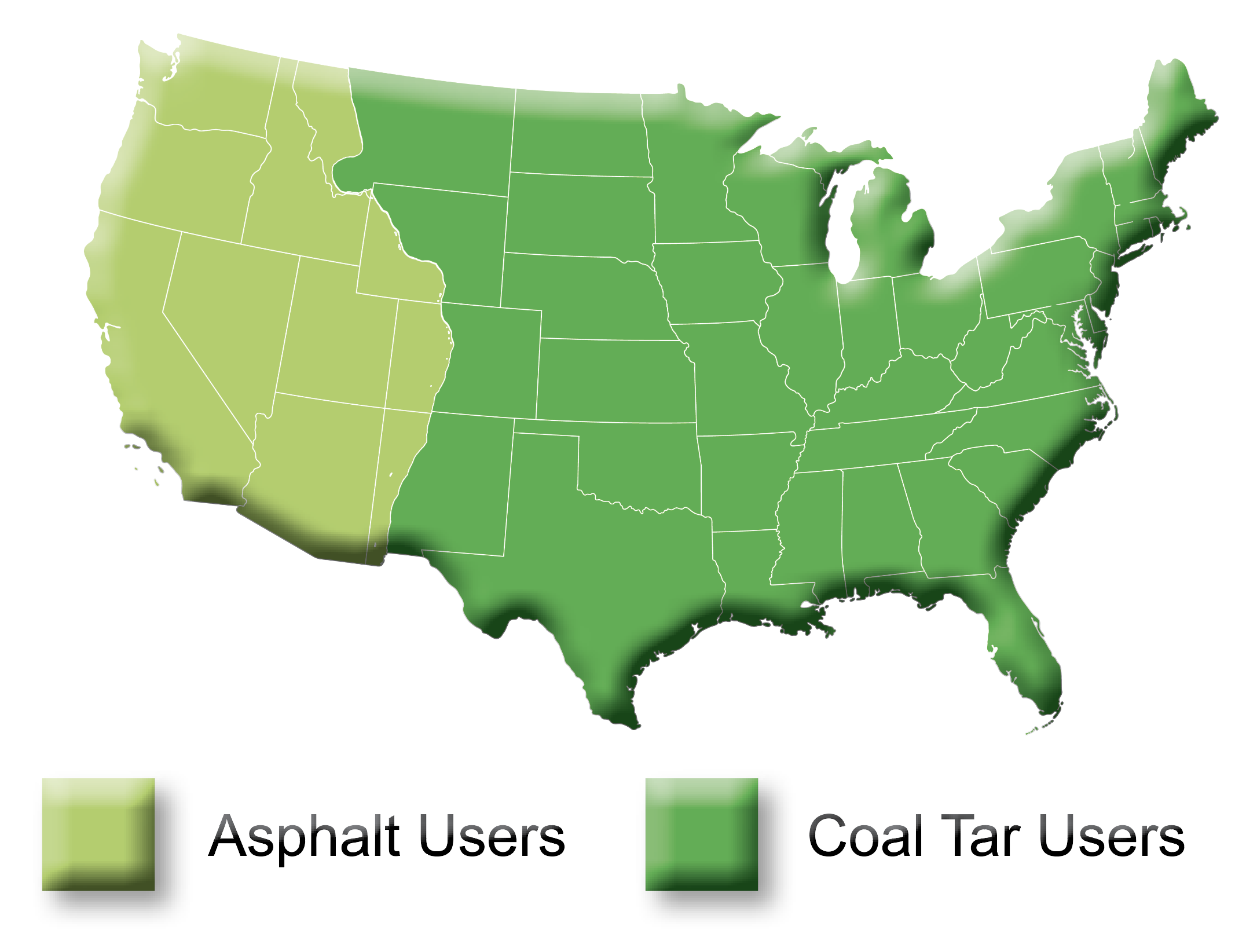

For decades, the sealcoating industry has been divided into two primary groups: contractors who use coal tar-based sealers and those who use asphalt-based pavement sealers. Historically, asphalt-based sealers have been favored by contractors west of the Rocky Mountains, while coal tar-based sealers have been favored by contractors to the east.

This geographical divide emerged largely from regional manufacturing, long-standing contractor familiarity and perceptions around performance. But as technologies evolve and environmental priorities shift, those lines are beginning to blur.

Why Coal Tar Sealers Have Historically Dominated the East

For decades, coal tar based sealers have been heavily promoted by manufacturers east of the Rocky Mountains, resulting in widespread adoption among pavement sealcoating contractors. It is the product they have historically relied on and become accustomed to using. Manufacturers have emphasized coal tar’s superior fuel resistance and overall durability as its primary advantages. Additionally, coal tar raw materials are more readily available in the east due to concentration of coking coal production and the historical industrial base of steelmaking in that region.

Why Asphalt-Based Sealers Lead in Western Markets

In contrast, manufacturers west of the Rockies have long advocated for asphalt-based sealers, resulting in broad acceptance among contractors and property managers. These products are frequently marketed for their ease of use, absence of harsh fumes, darker finish, and greater material flexibility. When properly formulated and applied, asphalt-based sealers offer sufficient fuel resistance and durability.

Chemical Differences: Coal Tar Pitch vs. Petroleum Asphalt

Before examining the advantages of each sealer type, it is important to first review the chemical differences between coal tar pitch and petroleum asphalt, as this understanding will help clarify the distinctions between the two sealers.

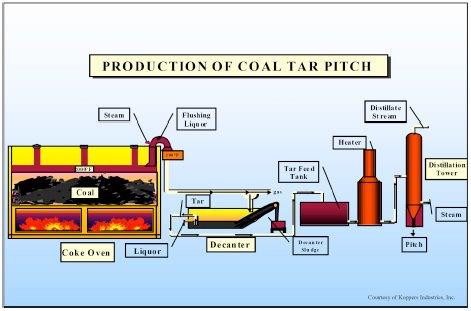

What is Coal Tar Pitch?

Crude Coal Tar is a by-product generated during the conversion of coal into coke for use as a fuel in steel production. This material undergoes refining to create RT-12 Coal Tar Pitch, which serves as a key ingredient in pavement sealer formulations. The closed-ring aromatic molecular structure of RT-12 provides excellent resistance to UV exposure and chemical degradation, with long-lasting durability.

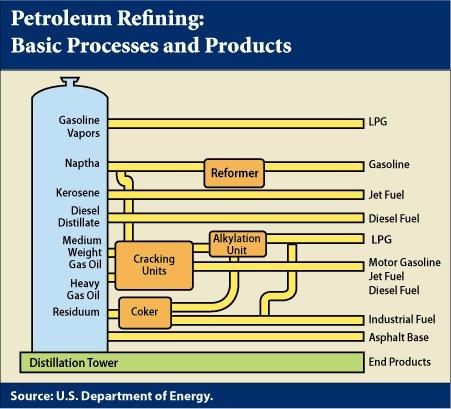

What is Petroleum Asphalt?

Petroleum Asphalt is a by-product of the oil refining process. Through vacuum distillation, asphalt is separated from other crude oil fractions such as Naphtha, gasoline, and diesel fuel. The resulting material is a highly viscous, black bitumen, known as asphalt. When emulsified with water and fillers, asphalt forms a smooth, workable pavement coating that contractors often describe as more “user-friendly.” This product is used in the production of hot-mix and cold-mix blacktop, as well as a wide range of asphalt-based sealers, coatings and waterproofing products.

Some of its benefits include:

- Low odor with no harsh or irritating fumes

- A richer black finish

- More flexibility, which can help resist cracking

Coal Tar Production

Asphalt Production

How Asphalt and Coal Tar Sealers are Made

Coal tar sealers are produced by combining water, fillers, and coal tar pitch and have historically been valued for their resistance to petroleum spills and chemical exposure. They cure to a hard, glossy finish. Benefits include:

- Strong resistance to oil, fuel and chemical spills

- Dark, glossy appearance immediately after application

- High surface hardness

Asphalt-based sealers are made by blending water, asphalt and fillers with polymers and performance additives. Because they are derived from the same material as asphalt pavement, they bond naturally with the surface. Benefits include:

- Excellent adhesion to asphalt surfaces

- Flexible finish that expands and contracts with temperature changes

- Environmentally friendly, with low levels of harmful chemicals

- Natural black appearance that restores pavement aesthetics

- Compliant with environmental regulations in most states and municipalities

Durability and Flexibility

While coal tar sealers and asphalt-based sealers both protect asphalt surfaces, they behave very differently once cured—especially under traffic stress and temperature changes.

Coal Tar Sealers

Coal tar sealers cure to a very hard, dense film, which initially provides strong surface protection. Its long-lasting durability:

- Creates excellent resistance to abrasion

- Establishes high hardness under traffic

- Performs well in chemically aggressive environments

However, due to its lack of flexibility, cracking and premature failure can occur, especially in freeze-thaw climates or regions with temperature extremes. Some limitations include:

- Limited elasticity after curing

- Becomes increasingly brittle with age

- Prone to cracking in freeze-thaw climates

- Cracks allow water infiltration, accelerating pavement failure

Asphalt-Based Sealers

Asphalt-based sealers are made from refined asphalt emulsions, closely matching the chemistry of the pavement itself, which increases durability aspects such as:

- Strong adhesion to asphalt surfaces

- Even wear under traffic

- Reduced flaking and peeling

- Consistent performance across seasonal changes

Because asphalt-based sealers remain flexible, which allows them to move with the pavement, cracking is reduced over time. This often delivers more predictable, longer-lasting protection. Some of those advantages include:

- Remain flexible after curing

- Expand and contract with pavement movement

- Resist cracking caused by thermal stress

- Better performance in freeze-thaw conditions

Fuel and Chemical Resistance

One of the biggest benefits of coal tar sealer is how well it stands up to harsh chemicals. It naturally resists:

- Gasoline

- Diesel

- Motor oil

- Common solvents

Asphalt-based sealers can also handle chemical exposure, but their resistance has traditionally been a bit lower. Rather, asphalt-based sealers offer good resistance to common non-petroleum chemicals, including:

- Water-based cleaners

- De-icing salts

- Mild detergents

- Environmental contaminants

Coal tar sealers outperform asphalt-based sealers when it comes to oil and fuel resistance, making them historically popular for gas stations and industrial sites. That said, modern asphalt-based sealers enhanced with polymer additives now offer improved resistance suitable for most commercial and residential applications.

The Eastward Shift: Growing Popularity of Asphalt-Based Sealers

During the last decade, asphalt-based pavement sealers have successfully expanded into markets historically dominated by coal tar products. Their enhanced user-friendliness and rich black appearance have resonated with contractors and property owners alike. SealMaster has been a key driver in this growth, advancing the adoption and acceptance of asphalt-based sealers east of the Rockies.

Future Outlook: Continued Growth and Innovation

Adoption of asphalt-based sealers throughout the eastern United States has increased substantially year over year. Current trends indicate that these products will gain even greater traction and popularity in the years ahead. To meet this demand, SealMaster has developed a range of advanced asphalt-based sealer technologies and remains committed to serving as a leading innovator in the asphalt pavement sealer sector.

SealMaster Expertise and Support

Successful sealcoating relies on thorough surface preparation, high-quality materials, and adherence to SealMaster’s proven best practices. With more than 60 years of experience and over 3 billion gallons of pavement sealer applied globally, SealMaster is widely recognized as the leading brand in pavement maintenance.

As a one-stop source for pavement solutions, SealMaster delivers premium products, equipment, and training through a franchise network of more than 125 manufacturing and distribution centers across North America, supplemented by product availability in over 60 countries. This broad presence ensures that contractors, municipalities, and property owners receive the resources and support needed to preserve and extend pavement life.

SealMaster’s nationwide network of professional contractors offers complete pavement maintenance services, including pothole repair, crack filling, sealcoating, and line striping. For expert assistance, product guidance, or to connect with a certified pavement specialist, contact your local SealMaster for a complimentary inspection or project estimate.