MASTIC MELTER AND APPLICATION EQUIPMENT | MASTIC MELTER APPLICATORS WITH TOOL HEATER | MASTIC PATCH AND REPAIR EQUIPMENT | CRACK SEALING MELTER APPLICATORS | OIL-JACKETED MASTIC MIXER

The SealMaster Crack Pro all-diesel mastic melter and applicator sets the industry standard for oil-jacketed mixing and melter applicators for hot-applied mastic material and features the industry’s fastest heat-up time. Crack Pro oil-jacketed mastic melter applicators for asphalt and concrete patching and repair are available in in 250- and 300-gallon capacities. SealMaster Crack Pro oil-jacketed mastic melter applicators are designed for melting and applying hot rubberized mastic for filling and leveling wide, transverse or longitudinal cracks and joints; distressed, alligatored pavement; rutted pavement; potholes; utility cuts; localized ski- patch repairs; and leveling bridge approaches or faulted areas.

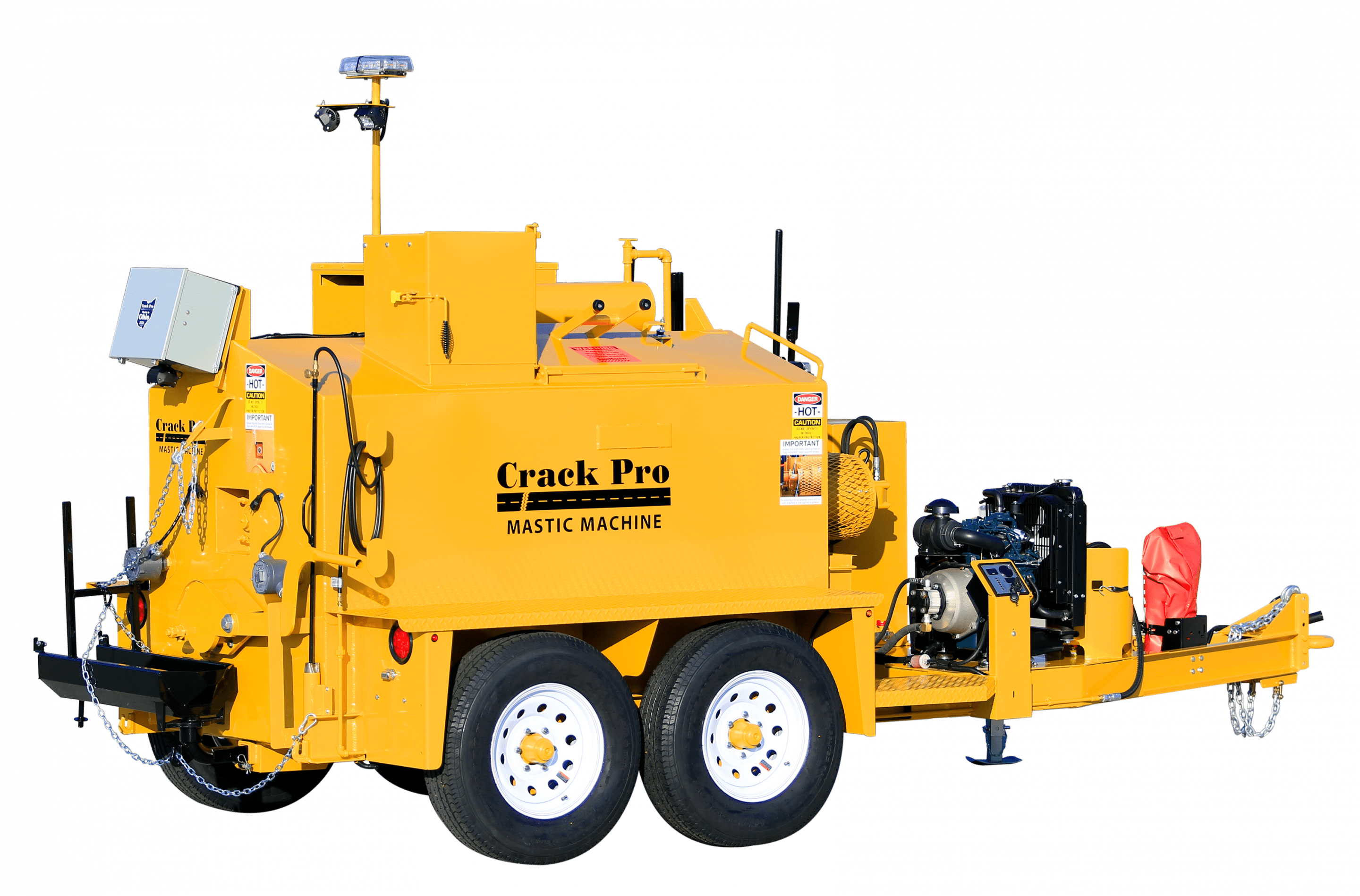

Crack Pro Mastic Machine

Available in 250 & 300 Gallon Capacities

Standard Features on Crack Pro Mastic Machine:

- Diesel engine and heating system. No propane required.

- Oil-jacketed kettle with fast heat-up time (Approximately 2.5 hours from a cold start).

- Plow-point agitation for faster heat-up, with forced material discharge.

- Agitation system provides unmatched power / torque with safety interlocks to protect the operator and prevent damage to the machine.

- Hydraulic system is highly efficient and designed to run cool (lowering maintenance costs), providing power to the torque-mounted, planetary agitation drive system.

- The waterproof steel control cabinet houses the Crack Pro brand’s proven control system.

- Burner temperature controllers with improved material temperature accuracy

- Safety interlocks

- Forward / reverse agitation switch

- Work and strobe lights

- Heavy duty, 6-inch adjustable knife discharge valve to cut through the mastic aggregate.

- Heated discharge chute stays hot without propane or hot oil and will not catch on fire when idle. The chute is easily removed for use with wheeled and hand-held applicators.

- Pail-warmer melts material from metal pails used in application.

- Large tool heater box utilizes a diesel-fired burner with automatic shutoff to prevent overheating tools and wasting fuel.

- Adjustable pintle eye to match hitch height, tandem axle, for good, stable towing and operation. Complete with battery powered break-away and LED light packages.

- Low-cost operation with highly efficient heating and low- horsepower requirements.

- The 30-gallon fuel tank allows 15 to 25 hours of operation between fill-ups.

- Overnight heaters allow for quicker application the next day.

- Maintenance is a breeze with a 600-degree-rated bearing on the rear and a packing gland with internal grease ports for direct lubrication into the gland on the front. This machine was built with maintenance in mind and easy access to all components that require periodic service. (burners, packing glands, grease Zerks, engine, and drive system).

Specifications:

| Model | CP 250 | CP 300 |

| Tank Capacity | 250 gallon | 300 gallon |

| Heat Transfer Oil | 35 gallons | 42 gallons |

| Max. BTU Input | 372,000 | 372,000 |

| Construction | Oil Jacket | Oil Jacket |

| Temp. Control | Digital | Digital |

| Tank Opening Material | 16″ x 24″ | 16″ x 24″ |

| Tank Opening Pail Heat | 16″ x 16″ x 16″ | 16″ x 16″ x 16″ |

| Insulation | 1.5″ | 1.5″ |

| Agitation Forward Reverse | Plow-point forced discharge | Plow-point forced discharge |

| Heating System | Diesel Burner | Diesel Burner |

| Power Unit Diesel | Kubota D 602 | Kubota D 602 |

| Tandem Axle Suspension | 6,000 lb. axles | 6,000 lbs. axles |

| Loading Height | 60″ | 60″ |

| Overall Height with Light Kit | 108″ | 108″ |

| Width | 82″ | 82″ |

| Length | 200″ | 212″ |