by DarioNMolly | May 16, 2016 | News, Uncategorized

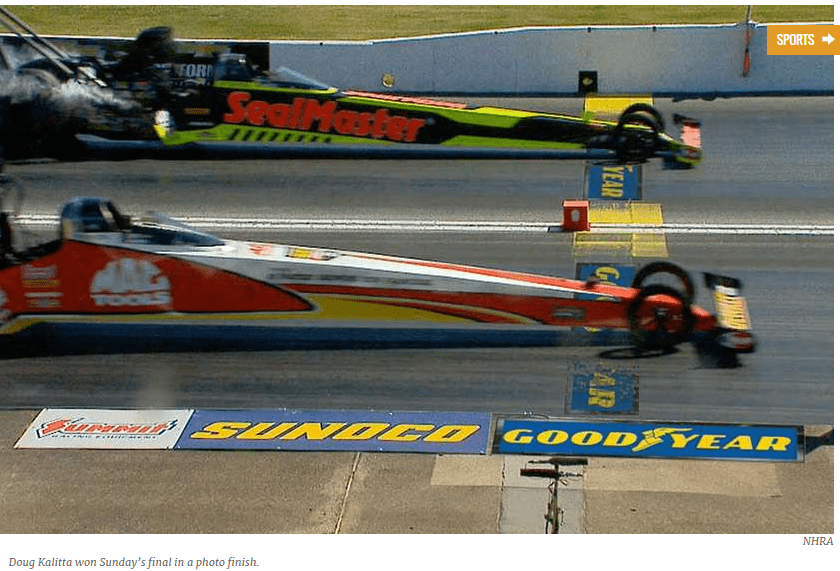

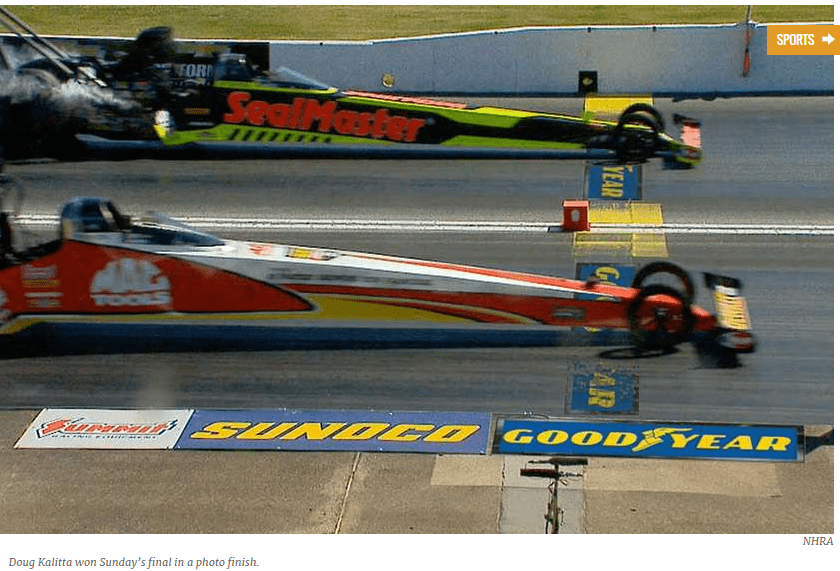

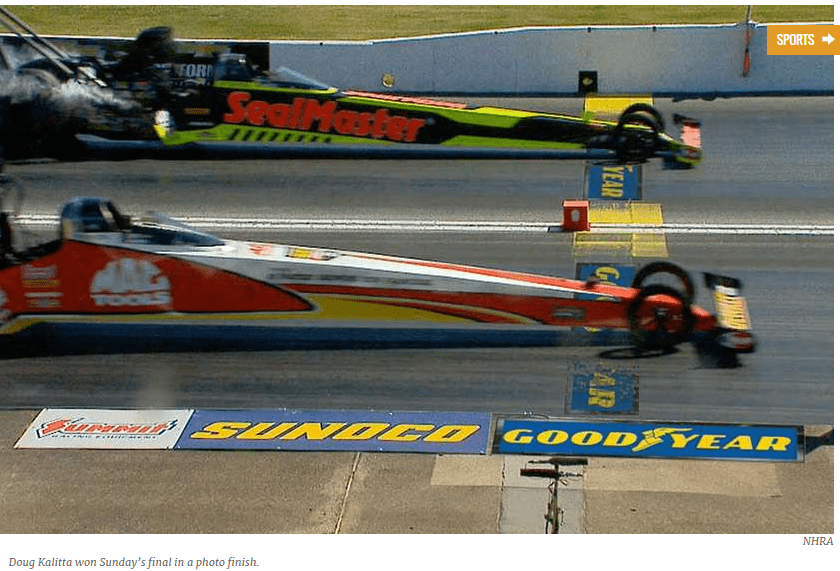

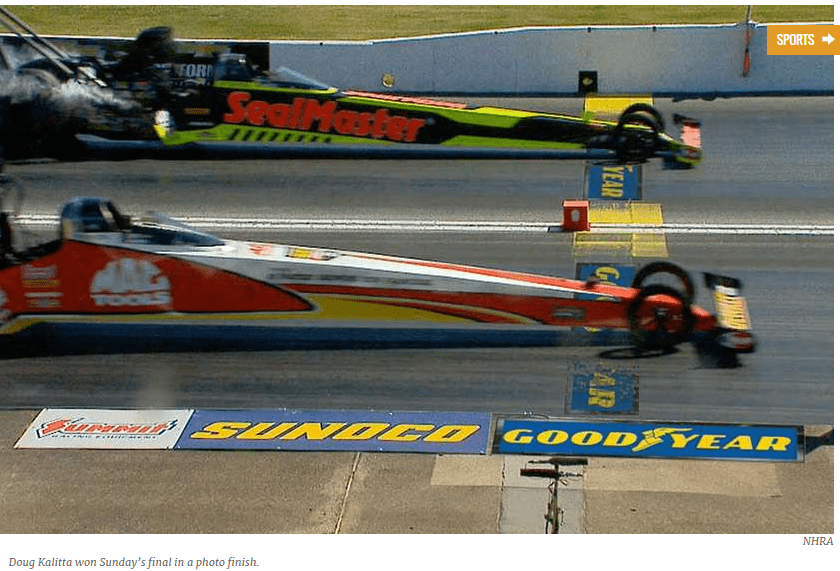

SealMaster NHRA Mello Yello Series Top Fuel partners Doug Kalitta and J.R. Todd now hold the distinction of running the closest race in NHRA history. With yesterday’s win, Doug Kalitta holds the No. 1 position in NHRA Mello Yello Series points and J.R. Todd...

by DarioNMolly | Apr 12, 2016 | News

SANDUSKY, Ohio (GLOBE NEWSWIRE) — Associa, the worldwide leader in community association management has officially partnered with SealMaster to offer property managers and homeowners within the Associa network the best sourcing solution for pavement maintenance...

by DarioNMolly | Apr 7, 2016 | Allentown Posts, News

CHARLOTTE, NC. (April 7, 2016) ““ Kalitta Motorsports and J.R. Todd, driver of the SealMaster Top Fuel dragster, are pleased to welcome NASCAR Camping World Truck Series (NCWTS) and ThorSport Racing drivers Rico Abreu, Matt Crafton, Cameron Hayley and Ben...

by DarioNMolly | Jan 13, 2016 | News

SealMaster and Kalitta Motorsports are pleased to announce SealMaster will become the primary sponsor of the Top Fuel dragster driven by J.R. Todd for the entire 2016 NHRA Mello Yello Series. “After having top-notch experiences with Kalitta Motorsports,...