by DarioNMolly | May 22, 2017 | News

Salt Lake City, Utah””SealMaster, a leading global supplier of pavement maintenance supplies and equipment, has opened a manufacturing plant, distribution center and retail showroom in in West Valley City and will serve the entire state of Utah. The business...

by DarioNMolly | Apr 26, 2017 | News

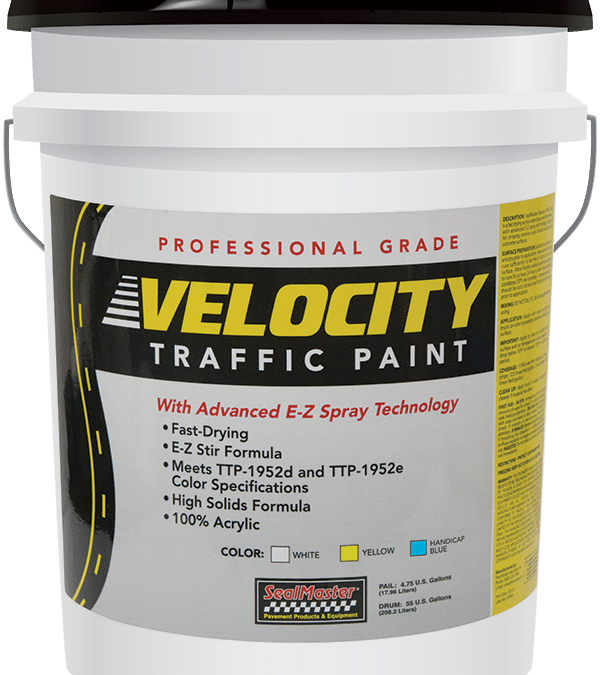

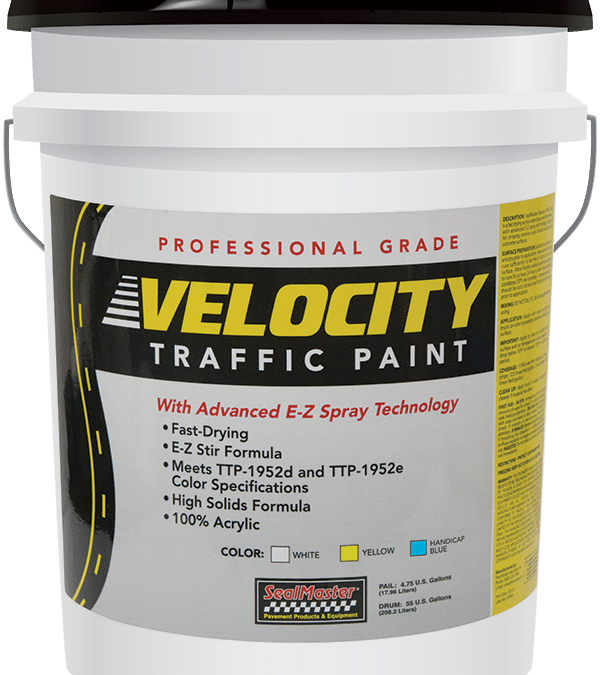

High performance prompts requests for new color In response to requests for Handicap Blue in the Velocity Traffic Paint line, the new color is now available. High performance and ease of use of the yellow and white formulas are driving market demand. Velocity...

by DarioNMolly | Apr 26, 2017 | News

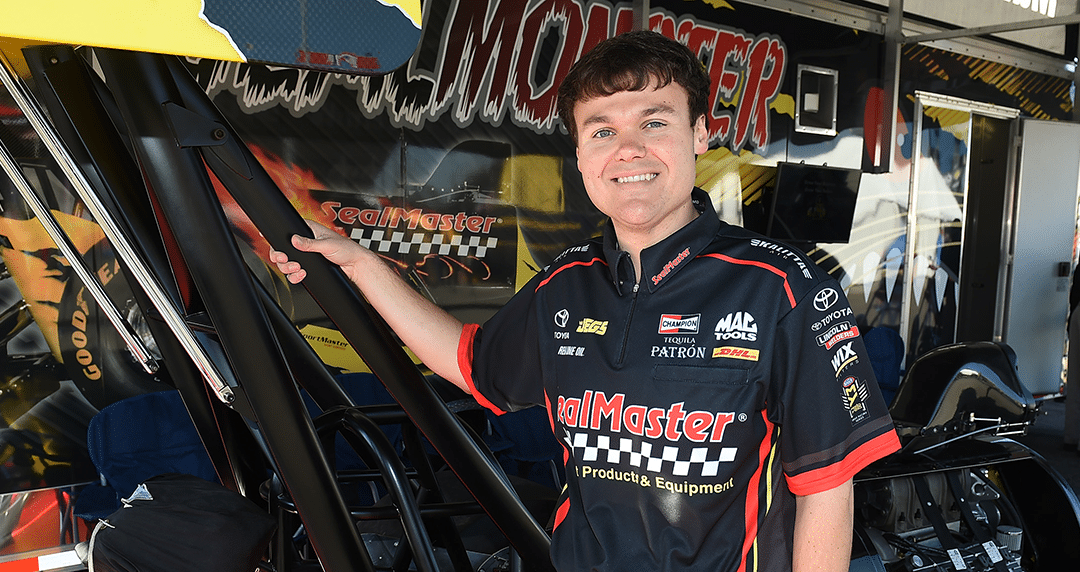

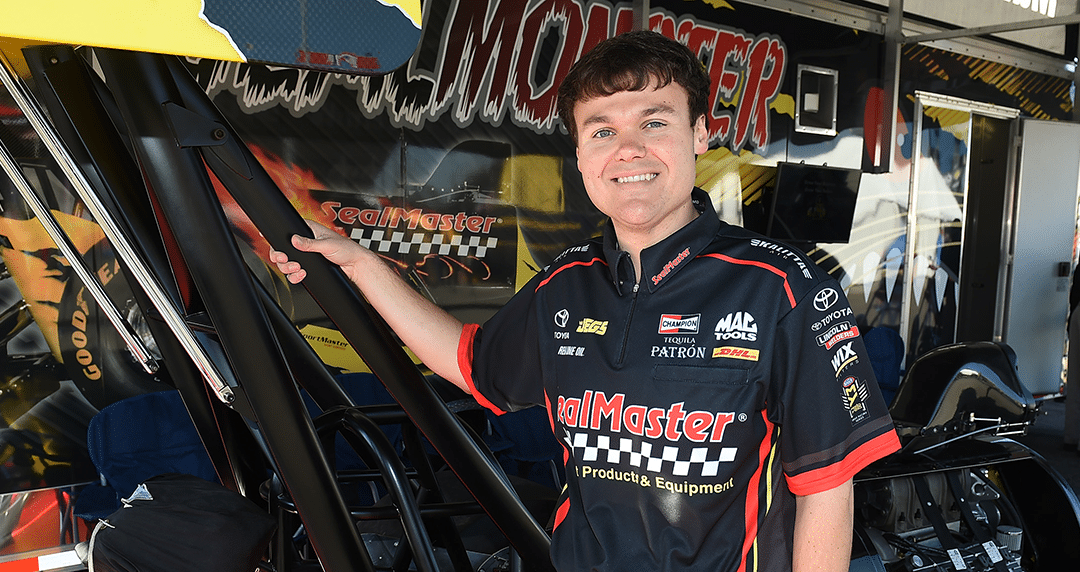

Greensboro, N.C. – National Hot Rod Association Driver Troy Coughlin Jr., who pilots Kalitta Motorsports’ SealMaster Top Fuel Dragster, will visit the boys and young men of the Greensboro Build Something Mentor Program Wednesday, April 26, at 7 p.m. at the...

by DarioNMolly | Nov 15, 2016 | News

SealMaster Crew Chief and Kalitta Motorsports founder and owner Connie Kalitta was honored last night at the season-ending Mello Yello Awards banquet with NHRA’s Lifetime Achievement Award. This is the first time in NHRA history that this award has been given. ...

by DarioNMolly | Oct 19, 2016 | News, Uncategorized

SANDUSKY, Ohio, (October 19, 2016) SealMaster, the pavement maintenance industry’s one-stop source for materials, products, and equipment, and Kalitta Motorsports are pleased to announce a contract extension for the 2017 season. SealMaster will continue as the...

by DarioNMolly | Sep 21, 2016 | News, Uncategorized

Click here for more information.